The world of Crimping Geometries

-

Introduction.

In the critical landscape of electrical installations, the choice of crimp geometry significantly influences the reliability and performance of connections. Elpress, a leader in innovative electrical solutions, presents a range of crimp geometries designed to meet and exceed industry demands.

-

Standard crimp geometries .

Standard crimp geometries, such as hexagonal and square forms, are the backbone of electrical connections, offering robust mechanical strength and dependable conductivity.These geometries are versatile, catering to a broad spectrum of cable types and sizes, making them a staple in electrical installations.

Advantages:

- Broad compatibility

- Proven reliability

Disadvantages:

- May not suit specialized applications requiring enhanced flexibility or specific connection attributes.

-

Elpress DUAL solution.

The Elpress DUAL technology is a groundbreaking approach that combines the advantages of hexagonal and indented crimping in one seamless operation.

This dual-action crimp enhances the contact interface and mechanical strength, significantly reducing the risk of wire fatigue and corrosion.

Advantages:

- Superior electrical conductivity

- Enhanced mechanical strength

- Reduced wire fatigue

Disadvantages:

- May necessitate specific training for optimal utilization.

-

Elpress DUAL5 innovation.

Building upon the DUAL concept, the DUAL5 solution is specifically engineered for highly flexible aluminum conductors, ensuring a smooth and uniform crimp across the conductor’s entire surface.

Advantages:

- Tailored for high-flexibility conductors

- Optimal conductivity and durability

Disadvantages:

- Requires specialized equipment and training.

-

Elevate your electrical connections.

Embrace the future of crimping technology with Elpress’s advanced solutions.

Whether you’re inclined towards the reliability of our standard geometries or ready to explore the cutting-edge DUAL and DUAL5 technologies, we’re here to ensure you find the perfect fit for your project needs.

-

Connect with us today!

Dive deeper into the world of superior crimping solutions. Request a demo, explore our full product range, or write to an Elpress expert to customize your crimping strategy.

Some of the most common Crimp Geometries

The abundance of crimping geometries stems from the diverse needs and specifications across various industries and applications. Each crimping geometry is carefully engineered to optimize electrical conductivity, mechanical strength, and reliability for specific conductor sizes, types, and terminal configurations.

Factors such as conductor material, insulation thickness, and environmental conditions all influence the choice of crimping geometry. For instance, a hexagonal crimp may be preferred for its uniform compression and high tensile strength, ideal for heavy-duty applications. In contrast, a trapezoidal crimp might offer better strain relief and resistance to vibration, making it suitable for automotive connectors.

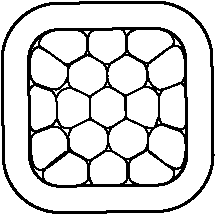

Hexagonal

In a hexagonal crimp, the material is folded into

a hexagon shape, offering a secure

connection with multiple angles of contact.

W-shape

In a W crimp, the material is folded multiple times in

a zigzag pattern, providing additional strength

and stability to the connection.

Roll

Roll crimping compresses and secures electrical

connections by rolling the metal around the

wire, ensuring a reliable and durable joint.

DUAL

The DUAL technology combines the desired properties

from an optimal hexagonal crimp with those of a

limited indent crimp. This results in tight contact

surfaces without damage to the conductor strands.

Punch

Punch crimping employs a mechanical punch to compress

and deform metal around the wire, creating a highly

secure and durable electrical

connection, suitable for heavy-duty applications.

Rectangle

Rectangle crimping provides enhanced stability and

conductivity compared to other crimping methods,

ensuring a secure and reliable electrical

connection for various applications.

Square

The square crimp involves folding the material

to form a square shape, providing

a strong and stable connection.

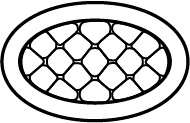

Oval

This crimp creates an oval-shaped closure,

often used in confined spaces

where a circular crimp isn’t feasible.

TRAPEZOID

This crimping geometry creates a

trapezoid-shaped closure,

offering a secure connection with angled edges.